30TPD wheat flour mill

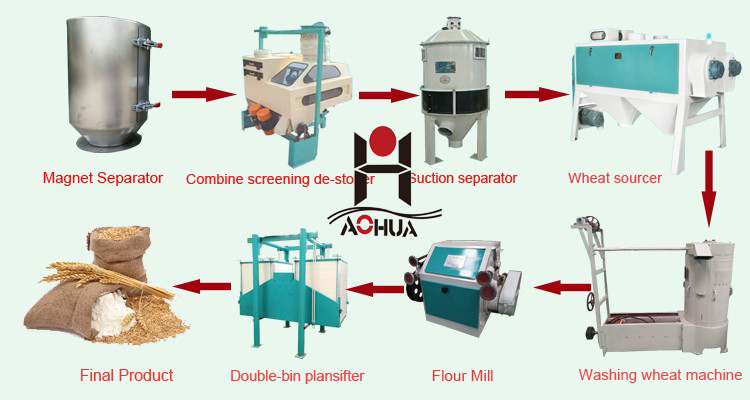

The complete flour mill can be divided into four parts: cleaning part, milling part, packing part and PLC control part.

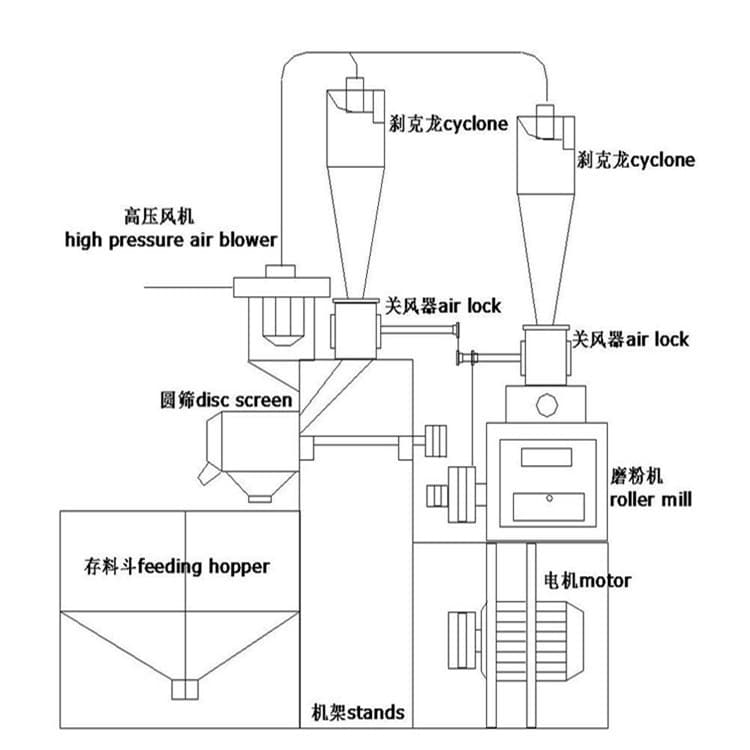

The complete set of wheat flour milling equipment can be divided into four parts: cleaning part, milling part, packaging part and PLC control part. Cleaning part: remove small and medium impurities in the wheat. Such as dust, stones, magnetic substances, insect bites on wheat, etc. Including beating, screening, stoner, magnetic separator and dampening. This part is to prepare for the milling part and also to protect the machine. In the second step, the grain is milled and the flour, bran and other by-products are separated. Milling: Grinding the grain, breaking the integrity by moving the rollers, Sieving: Separating by-products such as flour, bran, etc., also separating large grains from small grains to ensure flour quality. In the third step, the packaging machine can weigh the package manually or automatically. Control the normal operation of the whole set of machinery and display the working process.