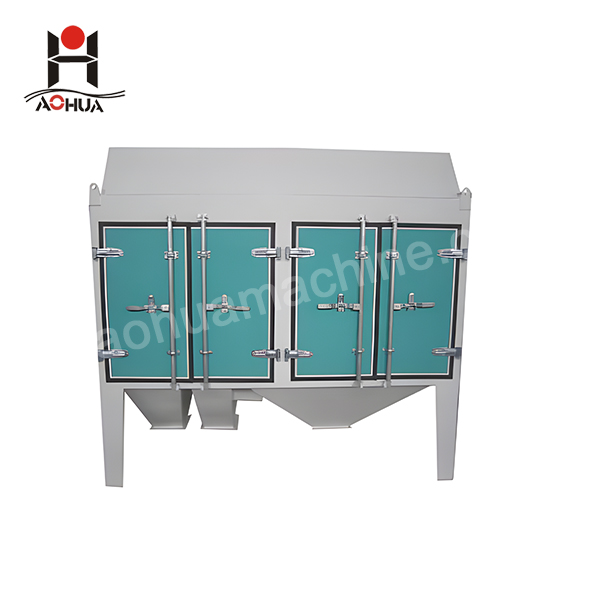

The Role of Rotary Vibrating Screens in Pulse Cleaning: Pre-Cleaning and Grading

The rotary vibrating sieve plays a dual role in bean processing. In the initial pre-cleaning stage, it effectively removes impurities like dust, stalks, and undersized particles from the raw beans. Subsequently, for grading, it precisely separates the beans by size into uniform fractions, ensuring consistency for further processing or packaging. This improves both product quality and processing efficiency.

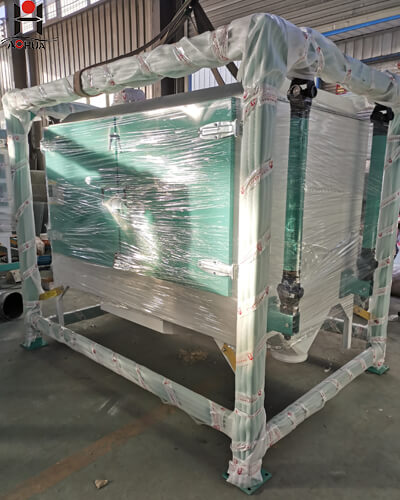

The rotary vibrating screen is a critical machine in the processing of pulses (such as lentils, chickpeas, beans, and peas), primarily serving two key functions: pre-cleaning and grading. Its efficient design ensures the removal of impurities and the separation of pulses by size, directly impacting product quality and downstream processing efficiency.

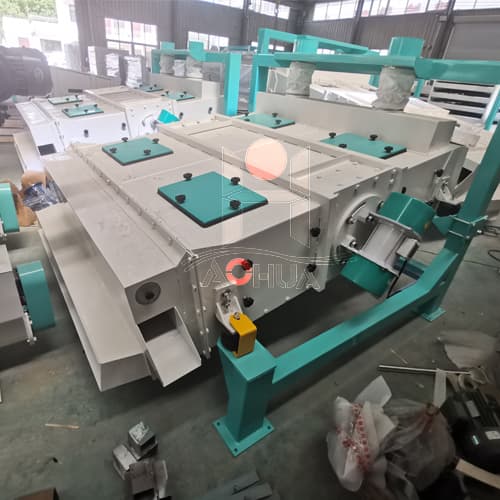

1. Pre-Cleaning

After harvest, raw pulses contain various impurities, including large foreign materials (like stalks, stones, clods), fine dust, and undersized or broken seeds. The rotary vibrating screen acts as the first line of defense in the cleaning process. Using a combination of vibratory motion and selected screen meshes, it effectively removes:

Large impurities: Stones, clods, and plant debris are separated over the top screen deck.

Fine contaminants: Dust, sand, and small particles pass through the bottom screen.

Undesired small/broken seeds: These are screened out through appropriate apertures, ensuring only sound, whole pulses proceed.

This pre-cleaning step is vital for protecting subsequent processing equipment (such as destoners or hullers) from damage and reducing the load on finer cleaning stages.

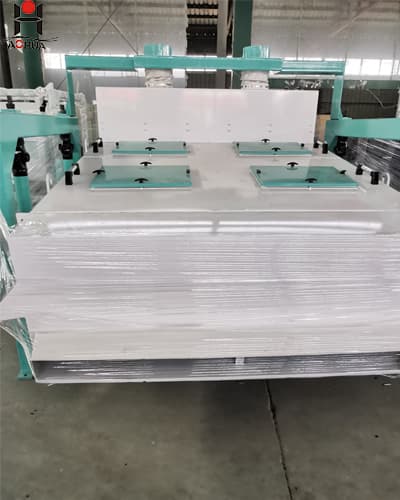

2. Grading

Following pre-cleaning, the rotary vibrating screen excels at size grading. Pulses are sorted into uniform fractions using decks with precisely sized openings. This is crucial for:

Quality standardization: Producing consistent sizes for retail or further processing (e.g., splitting, milling).

Process optimization: Uniformly sized pulses cook evenly and are better suited for mechanical dehulling or splitting.

Market value enhancement: Higher-grade, size-sorted pulses command better prices.

The screen’s adjustable vibration parameters (amplitude, frequency) and multi-deck configurations allow for precise separation with high throughput and minimal seed damage.

In summary, the rotary vibrating screen is an indispensable tool in pulse processing. By performing effective pre-cleaning and precise size grading, it ensures the removal of contaminants, improves product uniformity, and enhances overall processing efficiency, contributing directly to higher final product quality and operational profitability.