- Whatsapp:+86-13949074923

- Email: AoHua@aohuascreeningmachine.com

product

Your Position : Home > product > Feedstuff Processing Equipment

We're here to help: Easy ways to get the answers you need.

Products list

inquery

description

1. 10-20% higher yield than the previous crusher.

2. When the material comes in, the signalis transmitted to the electric control to drivethe crushing rolls to work, once there is nomaterial will be separated immediately.

3. Ensure the service life of crushing rolls.

4. Adopt the best uniform fabric device toensure the uniform pressure of the crushingrolls, which will crush the higher yield.

5. High crushing efficiency, low electricityconsumption, cost saving.

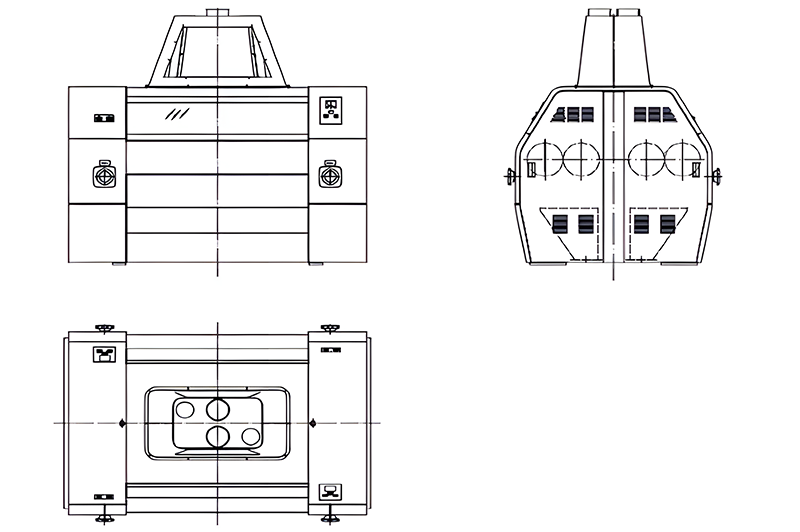

1. The Roller Mill Is The Main Processing Equipment For Grinding Corn And Miscellaneous Grains In A Corn Flour Mill.

2. It Mainly Relies On A Pair Of Grinding Rollers With Certain Technical Characteristics On The Surface, A Certain Speed Difference And Reverse Rotation To Break The Corn And Peel It From The Corn Husk. The Endosperm Is Ground Into Flour.

3. When The Mill Is Working, The Material Passes Through The Work Area Between The Slow And Fast Rollers, So That The Material Is Squeezed, Sheared And Scraped To Achieve A Certain Grinding Effect.

4. Each Mill Is Equipped With Two Independent Grinding Systems, And The Drive Of The Grinding Roller And The Feeding Roller Of Each System Is Independent, Which Plays Their Respective Functions In The System Milling Process.

|

Model |

Capacity(t/h) |

Power(kw) |

Weight(kg) |

Dimension(mm) |

|

AHPSJ25-80 |

3-5 |

7.5 |

1200 |

1550*845*1250 |

|

AHPSJ25-125 |

5-6 |

11 |

1800 |

1748*845*1250 |

-(2).jpg)

Similar items MORE

Pellet feed production lineThe feed production line pla...

Self Suction Feed Mill Multifunctional self - suct...

Rotary SifterTransmission system and scre...

Bucket Elevator TDTG vertical bucket elevat...

Feed MixerFeed mixer is the best produ...

Powder SifterBeautiful appearance, reason...

Please fill in your procurement needs and contact information