- Whatsapp:+86-13949074923

- Email: Dianaguo@aohuascreeningmachine.com

product

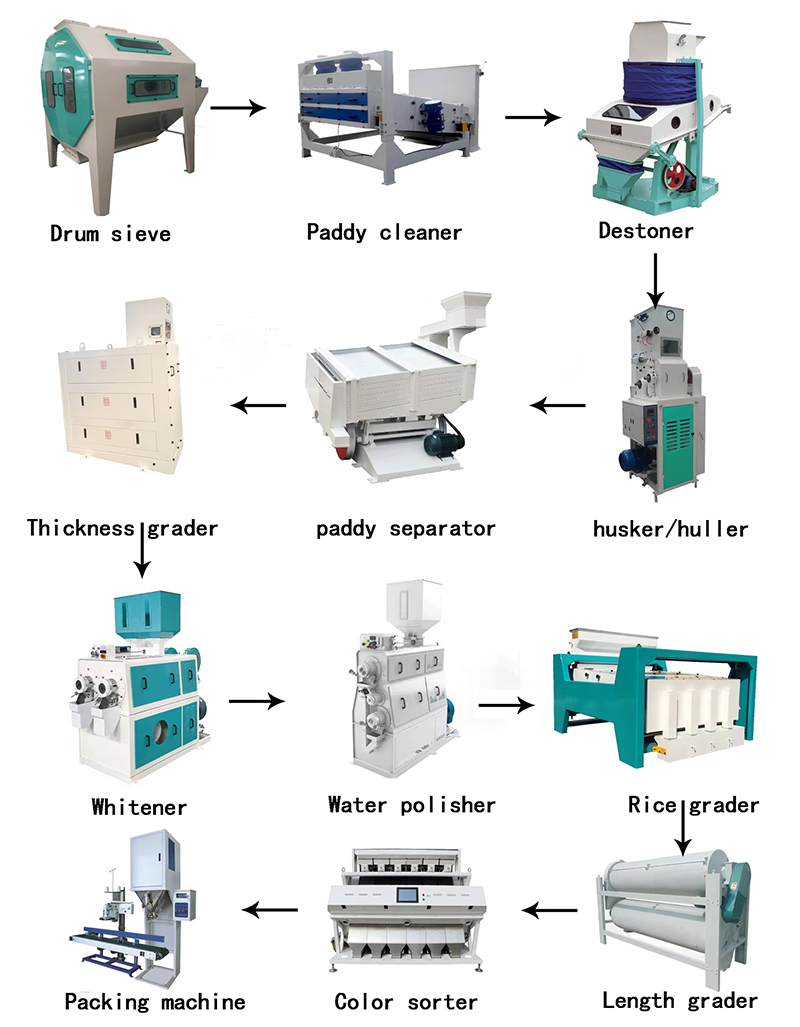

Your Position : Home > product > Rice Mill Complete Equipment

.jpg)

.jpg)

We're here to help: Easy ways to get the answers you need.

Products list

inquery

description

|

Rice Milling Machine Specifications |

||||||||

|

Type |

5T |

10T |

20T |

30T |

50T |

80T |

100T |

200T |

|

Capacity(T/D) |

5 |

10 |

20 |

30 |

50 |

80 |

100 |

200 |

|

Power(KW) |

29 |

74.4 |

84.9 |

97.4 |

125.35 |

208 |

245 |

530 |

|

Installation |

5*3*3.5 |

10*5*5.5 |

11*5*5.5 |

12*5*5.5 |

14*5*5.5 |

16*5.5*6 |

18*5.5*6 |

24*6*11 |

Similar items MORE

.jpg)

15TPD RICE MILL MACHINEIt has a high rate of produc...

.jpg)

40TPD Rice Mill PlantWith water polisher, color s...

20TPD Rice Mill Plant20tpd rice mill machine can ...

Please fill in your procurement needs and contact information