- Whatsapp:+86-13949074923

- Email: AoHua@aohuascreeningmachine.com

product

Your Position : Home > product > Wheat Flour Complete Equipment

.jpg)

.jpg)

.jpg)

We're here to help: Easy ways to get the answers you need.

Products list

inquery

description

.jpg)

|

Main capacity of wheat flour milling machine: |

|

|

No. |

Capacity |

|

1 |

5t/d single wheat milling machine |

|

2 |

10t/d single wheat flour milling machine |

|

3 |

20t/d complete wheat flour milling line |

|

4 |

30t/d complete wheat flour milling line |

|

5 |

50t/d complete wheat flour milling line |

|

6 |

60t/d complete wheat flour milling line |

|

7 |

80t/d complete wheat flour milling line |

|

8 |

100t/d complete wheat flour milling line |

|

9 |

150t/d complete wheat flour milling line |

|

10 |

200t/d complete wheat flour milling line |

|

Usages of finished wheat flour |

bread flour, bakery flour, pasta flour, cake flour, biscuit flour,etc. |

.jpg)

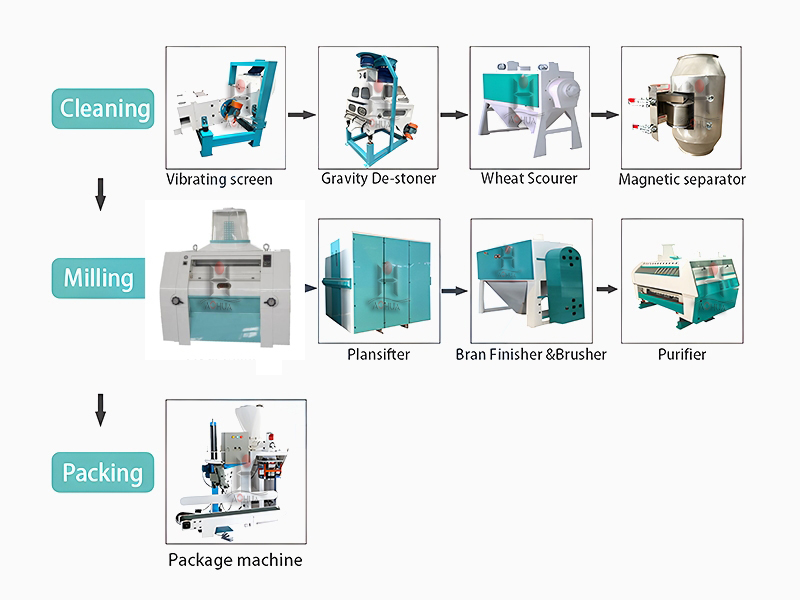

Complete set of wheat or maize flour machine can be divided into THREE parts:

.jpg)

1. Wheat flour roller mills are manufactured precisely and controlled by manual or pneumatic mode. It can make better grinding effect comparing with other ordinary mills.

2. Complete sets of wheat flour mill machine adopt various configuration modes for different choices. There are streamlined design, reasonable layout, beautiful performance .

3. It can be installed on a steel frame structure or in a concrete building.

4. The wheat flour mill machine is with advanced technical process and flexible adjustment.

5. Good after-sales service and spare parts is supplied for complete set of wheat flour mill machine.

.jpg)

1. Inner packing: Plastic film

2. Outside packing: Container/Wooden box

3. Shipping: By sea in QINGDAO port or according to your demand

Similar items MORE

.jpg)

Flour Mill MachineThe mini flour mill is small...

.jpg)

500TPD Wheat Flour Mill PlantComplete equipment of 500 to...

Barley Processing PlantA barley processing plant pr...

.jpg)

100TPD Wheat Flour Mill PlantThe 100-ton flour complete s...

60TPD Wheat Flour Mill PlantThis set of wheat flour mill...

30TPD Wheat Flour Mill PlantComplete set of wheat flour...

Please fill in your procurement needs and contact information