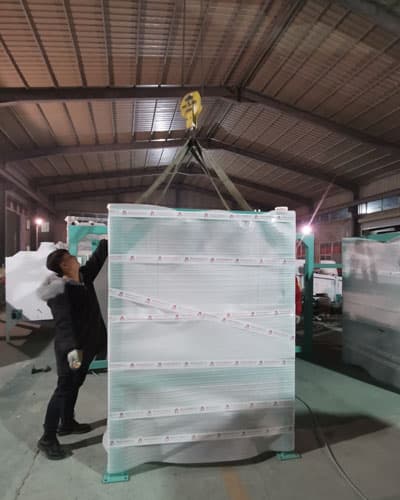

Grain Sesame Seed Cleaning Machine for Agriculture

In the pursuit of high quality and efficiency in modern agricultural product processing, optimizing every process means enhancing core competitiveness. The TQLZ high-efficiency vibrating screen, with its superior cleaning performance, extremely low breakage rate, and stable operating performance, has become an indispensable key piece of equipment in the sesame seed cleaning process. Investing in a suitable TQLZ vibrating screen not only ensures improved product quality but also is a wise move to reduce waste, increase production capacity, and promote industrial upgrading.

Sesame seeds are small and light in weight, often mixed with fine sand, dust, light impurities (such as straw and insect-infested kernels), and imperfect seeds. Cleaning them presents numerous challenges:

High precision requirements: Small sand and gravel are close in size to sesame seeds, making them difficult to separate completely. Once mixed into subsequent processes, they can seriously affect product taste and equipment safety.

High cleanliness requirements: Dust and light impurities can affect oil quality and food hygiene and safety standards.

Low crushing rate requirements: Sesame seeds are brittle, and vigorous cleaning methods can easily cause mechanical damage, increasing the risk of oil rancidity and resulting in economic losses.

High efficiency requirements: Traditional screening equipment has a low throughput, and the screens are prone to clogging, requiring frequent downtime for cleaning, which impacts continuous production.

The TQLZ high-efficiency vibrating screen is an advanced cleaning device that classifies materials based on particle size and specific gravity. Its efficiency stems from its sophisticated design and kinematic principles.

Unique Motion Trajectory: The equipment uses two vibration motors as excitation sources, generating bidirectional torque that causes the screen to move simultaneously horizontally and vertically, creating a complex rotational vibration. This motion causes the material to spiral forward on the screen surface, ensuring both sufficient agitation and dispersion of the material and effective screening time.

Multi-layer Screen Design: Typically, a two- or three-layer screen structure is used.

The first (upper) layer: features larger mesh openings, primarily used to remove impurities larger than sesame seeds, such as large pieces of straw and flax hulls.

The second (middle) layer: features precise mesh openings tailored to the sesame seed particle size, serving as the core cleaning layer. Qualified sesame seeds pass through the mesh openings, while slightly larger lumps of mud and foreign grains are retained and discharged.

The third (bottom) layer: features the smallest mesh openings, receiving sesame seeds that pass through the middle layer and ensuring further screening of fine impurities (such as fine sand and dust).

Elastic screen cleaning device: An elastic jumping ball or brush is arranged under the screen, which continuously impacts or cleans the screen when the equipment is running, effectively preventing the screen holes from being blocked and ensuring continuous, stable and efficient operation.