Millet Processing Plants

As a source millet processing factory, we specialize in converting high-quality raw grains into premium millet and deep-processed products.

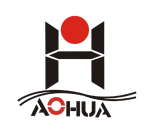

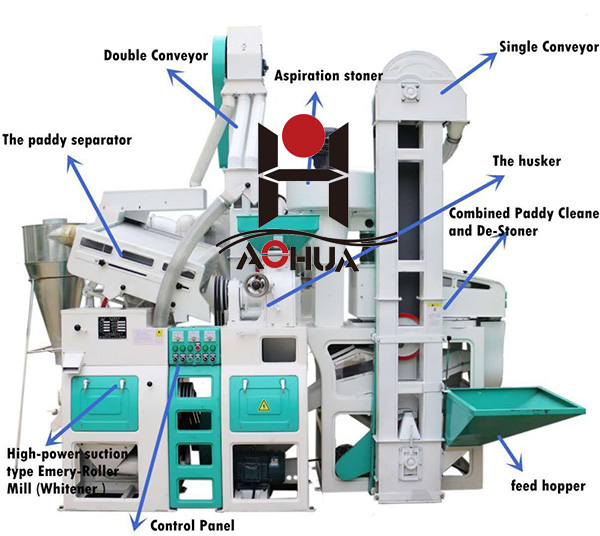

1. Vibratory cleaning sieve: Removes large particle impurities such as sand, stones, and straw.

2. Magnetic separator: Attracts and removes metal fragments to ensure the purity of the raw material.

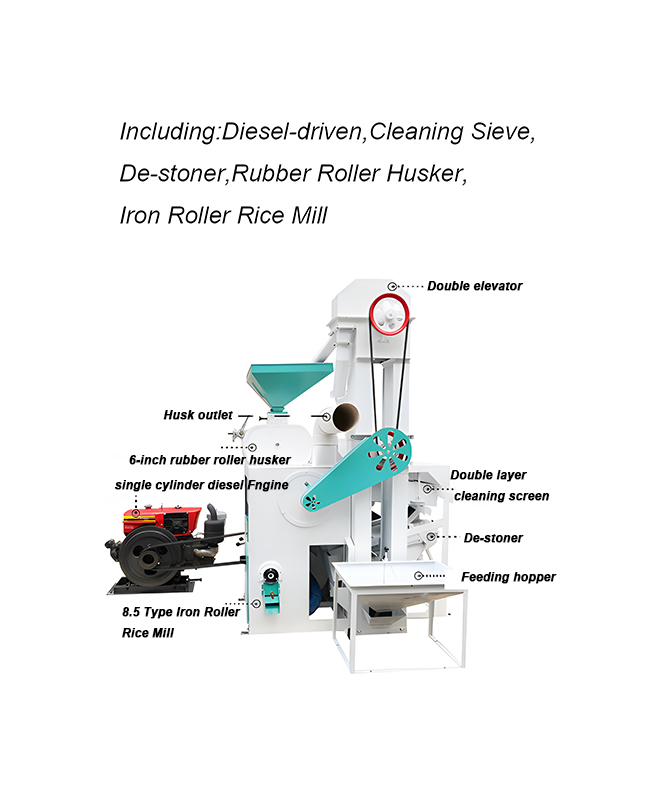

3. Huller: Strips the husk from the grain through pressure or centrifugal force, achieving a core shelling rate of 85%-95%.

4. Husk-and-brown rice separator: Separates unhulled grains for a second round of shelling.

5. Rice mill: Gently mills and polishes the grain kernels, enhancing the color and texture of the millet.

6. Color sorter: Utilizes AI-powered optical sorting to remove discolored and moldy grains.

7. Grading sieve: Classifies grains by size to ensure uniformity of the finished product.

8. Fully automatic weighing and packaging machine: Supports customization for specifications ranging from 5kg to 25kg, with a precision of ±0.5%.

The millet processing technology adopts a multi-stage light milling method. Firstly, the raw material undergoes impurity removal, cleaning, and husking to obtain clean millet. Then, it continues to remove the millet husks using a huller, as the husks are not edible for humans. After the husks are removed, the millet goes through processes such as rice milling and grading machines to obtain standard millet.

| Millet Milling Machine Specifications | |||||||

| Type | 10T | 20T | 30T | 50T | 100T | 150T | 200T |

| Capacity(T/D) | 10 | 20 | 30 | 50 | 100 | 150 | 200 |

| Power(KW) | 57 | 72 | 97.4 | 143.19 | 286.38 | 321.25 | 983.4 |

| Installation | 10*5*4.5 | 11*5*4.5 | 12*5*5.5 | 18*6*5.5 | 25*8*8 | 30*8*8 | 36*10*8 |