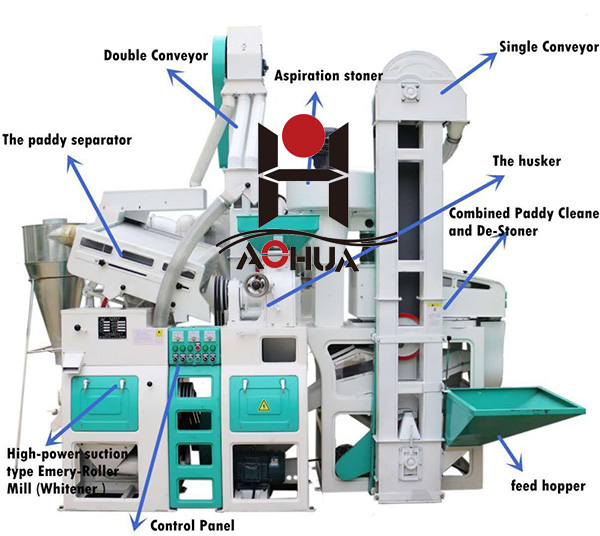

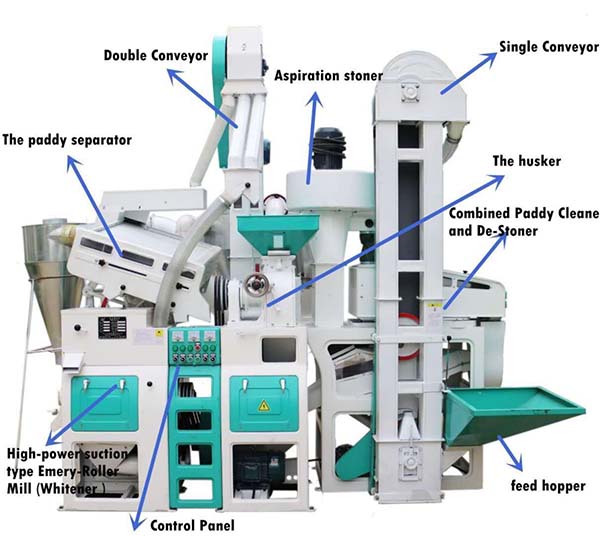

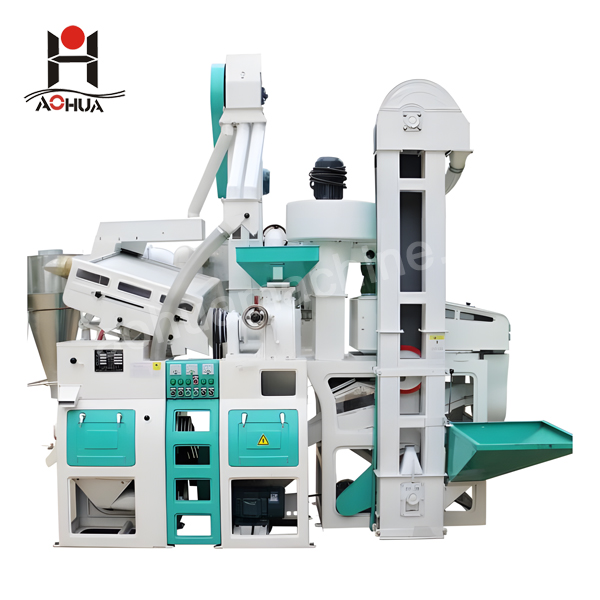

In a general rice mill, it mainly includes the pre-treatment stage, the rice milling core stage, and the post-treatment and sorting stage.

In the pre-treatment stage, we include cleaning impurities, cleaning stones, shelling.

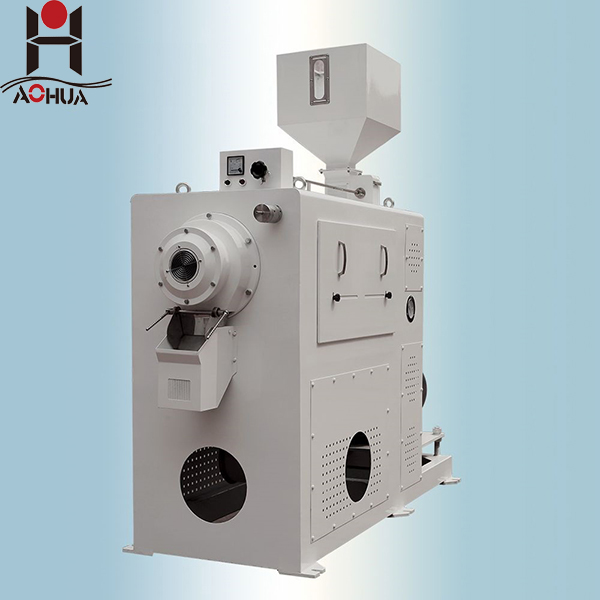

In the core stage of rice milling, it is generally divided into two grindings, namely the first whitening and the second whitening. Of course, the functions of the two grindings are also different. In this step, a polishing machine can also be added according to customer requirements to improve the glossiness of the material.

Post-processing and sorting stage, including grading screen, color sorting and packaging. Packaging can be a fully automatic packaging machine to improve the local automation to improve efficiency.

The high-quality transformation from paddy rice to polished rice is achieved through a combination of multiple processes, which requires balancing processing accuracy and broken rice rate, and taking into account both product and finished product quality.