Sorghum Dehulling/peeling And Kernel Making complete plant

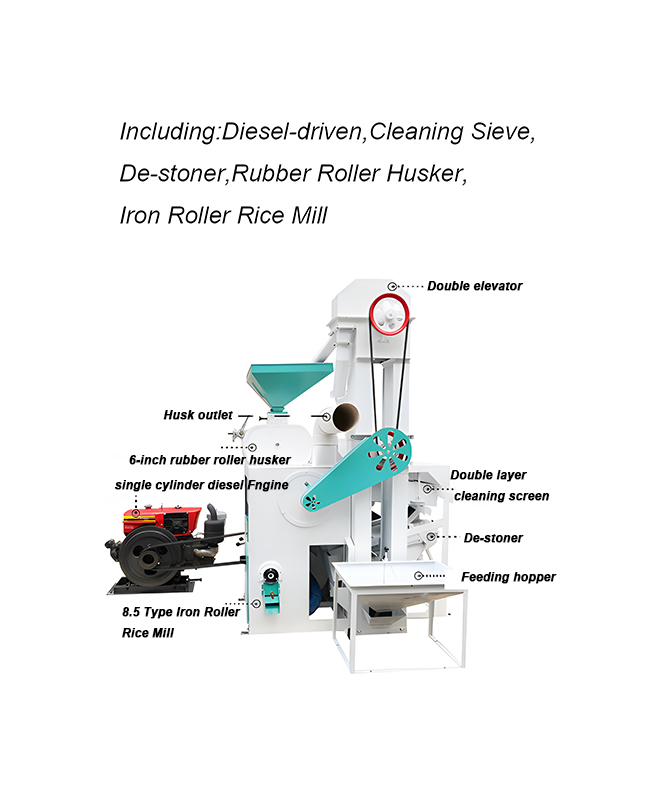

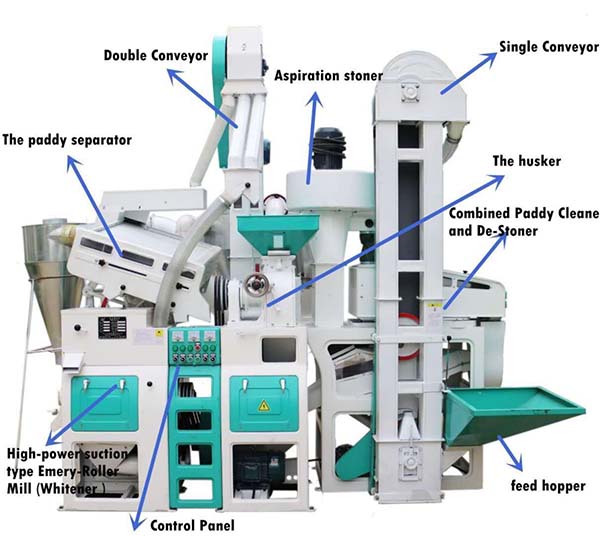

The project adopts a light peeling and multi-pass processing technology, which solves the problem of easy crushing and uneven grinding in traditional processes, and also reduces the problem of grain temperature separation during the production process.

The sorghum special peeling machine has the characteristics of high yield, low loss and low investment cost.

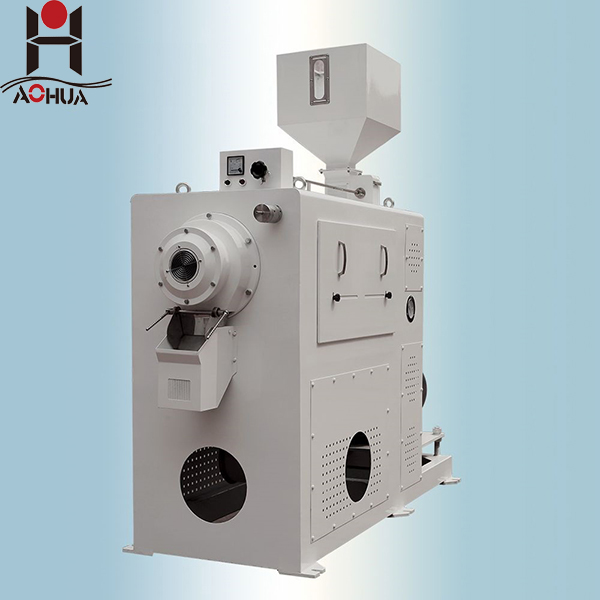

Key Machinery in Our Sorghum Processing Line

Cleaning & Destoning Machine – Removes impurities, dust, stones, and foreign materials for safe and hygienic processing.

Dehuller (Hulling Machine) – Gently removes the outer husk while preserving kernel integrity.

Polishing Machine – Enhances grain appearance and texture by refining the surface.

Gravity Separator – Classifies kernels by density to ensure uniform quality.

Grinding Mill (Hammer Mill/Roller Mill) – Processes sorghum into fine flour or coarse grits based on requirements.

Vibrating Sifter – Separates flour by particle size for consistent product quality.

Packaging Machine – Automatically weighs and packs sorghum products (flour, grits, or bran) in bags.